GOLD RECOVERY ION EXCHANGE RESIN

Maximizing Gold Recovery: Harnessing Ion Exchange Resin Technology

About Gold Extraction Resin

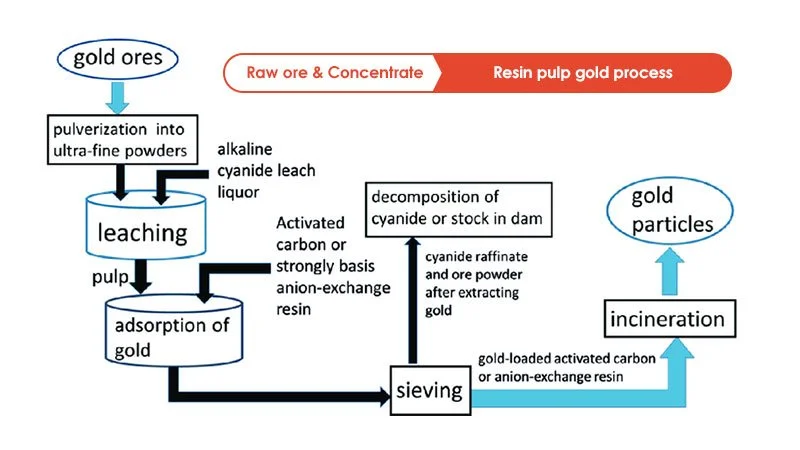

Gold extraction resin, also known as ion exchange resin or adsorbent resin, is a specialized material used in the extraction of gold from solution. It's an essential component in various gold recovery processes, particularly in hydrometallurgical techniques such as carbon-in-leach (CIL), carbon-in-pulp (CIP), and resin-in-pulp (RIP) processes.

key features and functions:

High Selectivity: Gold extraction resin has a high affinity for gold ions, enabling it to selectively adsorb gold from complex solutions containing a mixture of metals and impurities.

Porous Structure: The resin typically has a porous structure with a high surface area, which enhances its capacity to adsorb gold ions efficiently.

Chemical Stability: Resins used for gold extraction are designed to be chemically stable in harsh environments, such as acidic or alkaline solutions, ensuring their performance and longevity.

Regenerability: Some types of gold extraction resin can be regenerated after adsorbing gold, allowing for multiple cycles of use and reducing operational costs.

Ease of Handling: These resins are often supplied in a convenient form for industrial use, such as spherical beads or cylindrical pellets, making them easy to handle and integrate into existing extraction processes.

Compatibility: Gold extraction resins are compatible with various leaching solutions and can be used in conjunction with other materials like activated carbon to optimize gold recovery.

Environmental Considerations: Using resin for gold extraction can offer environmental benefits compared to traditional methods like cyanidation, as it can reduce the use of hazardous chemicals and minimize the production of toxic waste.

Overall, gold extraction resin plays a crucial role in modern gold recovery operations, offering an efficient and environmentally sustainable alternative to conventional extraction methods.

Carbon-in-Leach (CIL) and Carbon-in-Pulp (CIP) Processes: In these techniques, gold extraction resin is often used alongside activated carbon. After gold is leached from the ore with cyanide solution, the solution containing dissolved gold ions is passed through a series of tanks containing carbon and resin. The activated carbon adsorbs the gold cyanide complex, while the resin selectively adsorbs free gold ions that escape adsorption by carbon. This dual adsorption process enhances gold recovery efficiency.

Resin-in-Leach (RIL) and Resin-in-Pulp (RIP) Processes: These processes involve the direct use of gold extraction resin without activated carbon. After leaching gold-bearing ores with cyanide solution, the pregnant solution is directed through resin-filled columns or tanks. The resin selectively captures gold ions from the solution, allowing for efficient gold recovery. The loaded resin is then subjected to desorption to recover the captured gold.

Selective Gold Recovery: Gold extraction resin is employed for selective recovery of gold from complex solutions containing a mixture of metals and impurities. Its high affinity for gold ions enables it to selectively adsorb gold, even in the presence of competing metal ions. This selective adsorption facilitates the concentration and purification of gold from solution, leading to higher overall recovery yields.

Gold Recycling and Refining: Gold extraction resin is used not only in primary gold recovery from ores but also in secondary processes such as recycling and refining of gold-containing materials. Resin-based extraction techniques can be applied to various gold-bearing materials, including electronic waste, scrap jewelry, and gold-plated components, allowing for efficient recovery of gold from diverse sources.

Environmental Remediation: In addition to its usage in gold mining and metallurgy, gold extraction resin is employed in environmental remediation efforts. It can be utilized for the removal of trace amounts of gold from contaminated water or wastewater streams, contributing to the cleanup of environmental pollution caused by mining activities or industrial processes.