Important Properties of Ion Exchange Resin

Ion exchange resins, versatile materials with unique chemical structures, exhibit properties critical for a myriad of applications. From ion selectivity and capacity to mechanical stability and thermal resilience, understanding the diverse properties of these resins is paramount for their successful deployment in processes ranging from water purification to chromatographic separations.

Some of the Physical and chemical properties are given below:

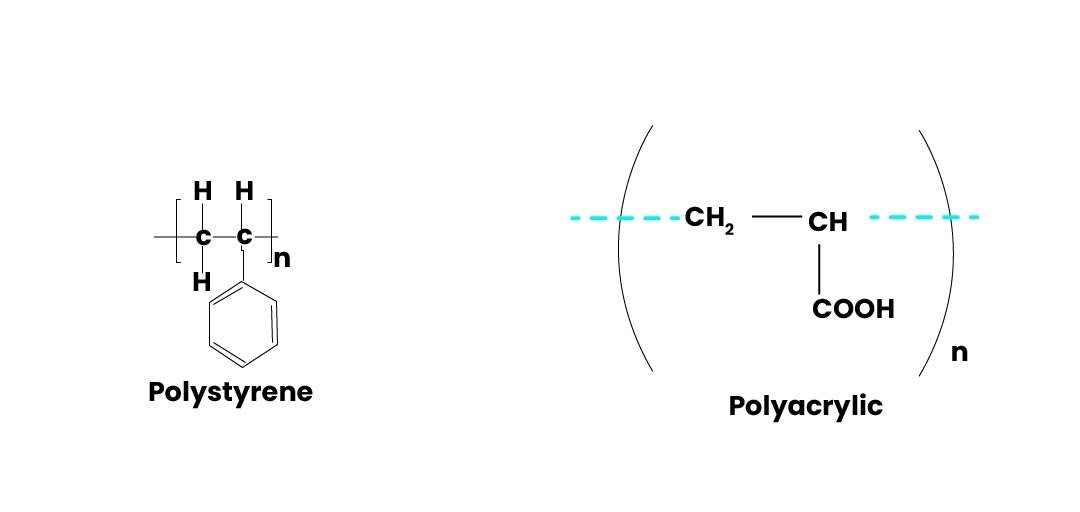

Basic Chemical Composition and Functional Groups :

Ion exchange resins play an indispensable role in various applications such as chromatography and water softening.

Ion Exchange Capacity :

Represents the amount of ions that can be exchanged/stored per unit of mass of the resin. Typically is expressed in milligrams of ion per gram (mg/g) of resin capacity.

Total exchange Capacity: Total exchange capacity is the total number of sites available for exchange. It is typically determined once the resin has been transformed into a specific ionic form using chemical regeneration techniques. Subsequently, the ion is extracted chemically from a precisely measured amount of resin and quantified in solution using standard analytical techniques. It is expressed on a dry weight, wet weight, or wet volume. The characteristics of the polymer backbone and the sample's surroundings affect a resin's ability to absorb water, which in turn affects its wet weight and wet volume capacities.

Operating exchange Capacity: The useful performance that the ion exchange material achieves when it operates in a column under specific conditions is measured by its operating capacity. It depends on several factors, such as temperature, particle size and distribution, regeneration level, composition of solution treated, flow rates through the column, and inherent (total) capacity of the resin.

Selectivity of Ion Exchange Resin

It can be defined as preference of Ion exchange material for one ion over another.

Selectivity Coefficient:

Qs = [A+]s [RnBn+1]R

[RA+]R [Bn+1]S

Where S and R denote the solution and resin concentrations, respectively.

Qs = 1 no preference for A+ over Bn+1

Qs > 1 Bn+ is preferred over A+

Qs < 1 A+ is preferred over Bn+

Particle Size

Most ion exchange resins used in industries come in sizes between 0.3 to 1.2 mm, including a wide range of sizes. However, there are specialized resins available that have uniform particle sizes of 0.5-0.7 mm.

Effective size :

Effective particle size of resin indicates the particle size of majority of resin beads. It is an indirect measure of average bead size. Effective size can be estimated by passing the resin through wet sieving. The resin is sieved once it has entirely absorbed and swollen, and the residual quantity is gathered on the 20, 30, 40, 50 mesh screen, through which 90 percent of the particles can pass. Generally, resins have 0.45-0.6 mm effective size.

Uniformity Coefficient :

The uniformity coefficient expresses how uniform the resin particles are. It can be calculated as the ratio of mesh opening with 40% retention to mesh opening with 90% retention.

Bulk Density/ Shipping weight : Bulk density varies from resin to resin and depends on ionic form. Bulk density/Shipping weight indicates weight per volume of resin. It is an important property of as resins are packed by weight and supplied by volume. The weight of the resin as supplied which will occupied 1 m3 in a unit after backwashing and draining.

Swelling : When resin comes into contact with solvent, resin can increase in volume. Ion exchange resins are hygroscopic in nature. The type of functional group, polymer structure, and the degree of cross-linking in a resin determine how much moisture it hydrates. Low cross-linking gel resins that have quaternary ammonium or sulfonic acid functional groups swell because they contain a lot of water. The resin life is shortened by frequent expansion and contraction. Swelling is typically expressed as the percentage increase in volume or weight of the resin when exposed to a specific solvent.

Mechanical Stability : Higher mechanical strength and abrasion resistance of ion exchange resins is essential to withstand rigorous manufacturing conditions and thus increases resin’s longevity. Good mechanical stability also resists deformation under pressure. Resin can be degraded if it undergoes many expansion-contraction cycles, thus some flexibility in resin structure is beneficial.

Chemical Stability : Higher chemical stability ensures resin to remain stable at higher pH and Temperature ranges. Good chemical stability offers resistance against acids, bases and other reactive chemicals. Ion exchange resins can degrade chemically due to a variety of factors, including breaking polymer structures, fouling the resin pores by precipitates (e.g. Iron hydroxide), and functional group modifications that result in a loss of ion exchange capacity.

Solubility : The ion exchange resin should ideally be insoluble. During operation, the substances produced by the degradation of the resin and the compounds added with a low degree of polymerization during the resin synthesis process will dissolve. Resins that have less cross-linking and more active groups are more likely to disintegrate.

Kinetics : The speed with which ion exchange takes place. The ion exchange process involves diffusion through the film of solution that is in close contact with the resins and diffusion within the resin particle. Film diffusion is rate-controlling at low concentrations and particle diffusion is rate-controlling at high concentrations. Whether film diffusion or particle diffusion is the rate controlling mechanism, the particle size of the resin also is a determining factor. Uniform particle sized resins exhibit enhanced kinetic performance compared to conventional polydispersed resins due to the absence of kinetically slow larger beads.

References:

( 1 ) https://www.netsolwater.com/what-are-the-physical-properties-of-ion-exchange-resins

( 2 ) https://www.lenntech.com/Data-sheets/Dowex-Ion-Exchange-Resins-Fundamentals-L.pdf

( 3 ) https://slideplayer.com/slide/10309896/

( 5 ) https://cnchiwatec.com/physical-properties-of-ion-exchange-resin.html

( 4 ) https://www.netsolwater.com/what-are-the-physical-properties-of-ion-exchange-resins.php?blog=3044

( 5 ) https://www.substech.com/dokuwiki/doku.php?id=ion_exchange_resins#properties_of_ion_exchange_resins

Explore Doshion's industrial water treatment resins for process transformation. Visit Doshion's Industrial Water Treatment Resins page : https://www.doshionpoly.com/ion-exchange-resin